Clean, safe water is vital for every day life. Water is essential for health, hygiene and the productivity of our community.

The water treatment process may vary slightly at different locations, depending on the technology of the plant and the water it needs to process, but the basic principles are largely the same. This section describes standard water treatment processes.

Products & Solutions

Antifoams & Defoamers

Unwanted foaming can be problematic in many commercial, manufacturing and industrial process applications, consequently it requires careful control measures to minimise or eliminate its impact. To ensure systems are well maintained and operate at optimum efficiency it is essential that the correct water conditions are maintained at all times.

Biocides & Disinfectants

Accepta’s range of advanced technology biocides and disinfectants have been developed for use in a wide range of commercial cleaning, disinfection, environmental hygiene, industrial and process water treatment activities where the effective control of microbiological activity in water and on surfaces is essential.

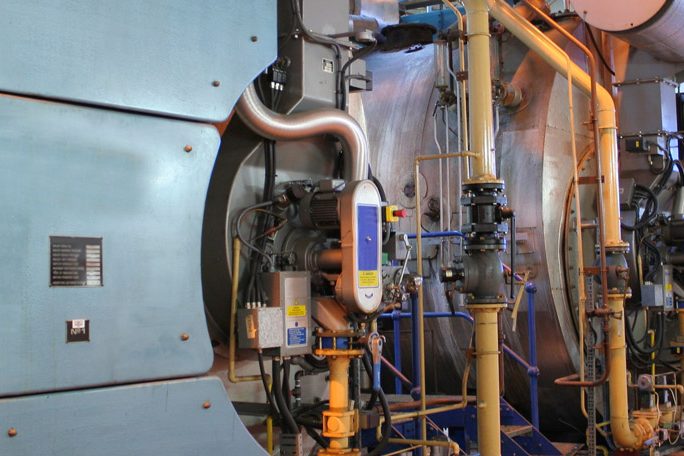

Boiler Water Treatment Chemicals

To ensure that such boiler systems are correctly maintained and operate at optimum efficiency it is essential that the correct boiler water conditions are maintained at all times. This can be achieved using carefully selected boiler water treatment chemicals.

Coagulation / Flocculation

During coagulation, liquid aluminium sulfate (alum) and/or polymer is added to untreated (raw) water. When mixed with the water, this causes the tiny particles of dirt in the water to stick together or coagulate. Next, groups of dirt particles stick together to form larger, heavier particles called flocs which are easier to remove by settling or filtration.

Cooling Water Chemicals

To ensure such cooling systems are correctly maintained and operate at optimum efficiency it is essential that the correct cooling water conditions are established and then maintained at all times. This can be achieved using carefully selected cooling water treatment chemicals.

Disinfection

Water is disinfected before it enters the distribution system to ensure that any disease-causing bacteria, viruses, and parasites are destroyed. Chlorine is used because it is a very effective disinfectant, and residual concentrations can be maintained to guard against possible biological contamination in the water distribution system.

Detergent

Detergent powder, also known as laundry detergent or washing powder, is a type of cleaning agent specifically designed for use in washing machines to clean clothes and other fabrics. It is a crucial product in household cleaning routines and has significantly simplified the process of cleaning clothes, linens, and other washable items.

All FEED

This publication is a revision of the previous swine nutrition publi- cation prepared by the University of Nebraska and South Dakota State University. The focus of the publication continues to be on nutrient recommendations for swine.

PAPER CHEMICAL

FEED

POULTRY FEED

SWINE FEED

CATTLE FEED

FISH FEED

DETERGENT

OCEA CLEAN

LIQUID DETERGENT

TOILET CLEANER

FLOOR CLEANER

DIENKING CHEMICALS

PULPING CHEMICALS

PAPER ENZYMES

TISSUE CHEMICALS

WATER MANAGEMENT

All TYPE FILLERS

- Writing Printing Fillers

- Duplex Board Fillers

- Craft Paper Fillers

The use of fillers in paper and paperboards grades are examined. The idea

was to get to know the concept of fillers and how to use more of them in papermaking.Replacing fibres with fillers is a major theme in this work.

This work was done in order to familiarize the field of paper industry and its uses offillers. Fillers are used in nearly every paper and paperboard grade. Filler use has increased during the last decades and continues to do so. Fillers bring special properties for paper products that could not be achieved in any other way.

STARCH

- Native & Maze Starch

- Cationic Starch

- oxidize Starch

In the wet part of the papermaking process, typically cationic starches, which have a positive charge bound to the starch polymer, are used.

Cationic starches, together with other retention and internal sizing agents, help to give the necessary strength properties to the paper web formed in the papermaking process (wet strength) and to the final paper sheet (dry strength).

In the dry end of the papermaking process, the paper web is rewetted with a starch-based solution. The process is called surface sizing. Starches used typically are chemically or enzymatically de-polymerized at the paper mill or by the starch industry (oxidized starch).

Starch is also used in paper coating as one of the binders for the coating formulation, which is a mixture of pigments, binders and thickeners. Coated paper has improved smoothness, hardness, whiteness and gloss, and thus improves printing characteristics.